Téléphone :

+86 13828 600940

Adresse physique :

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, Chine

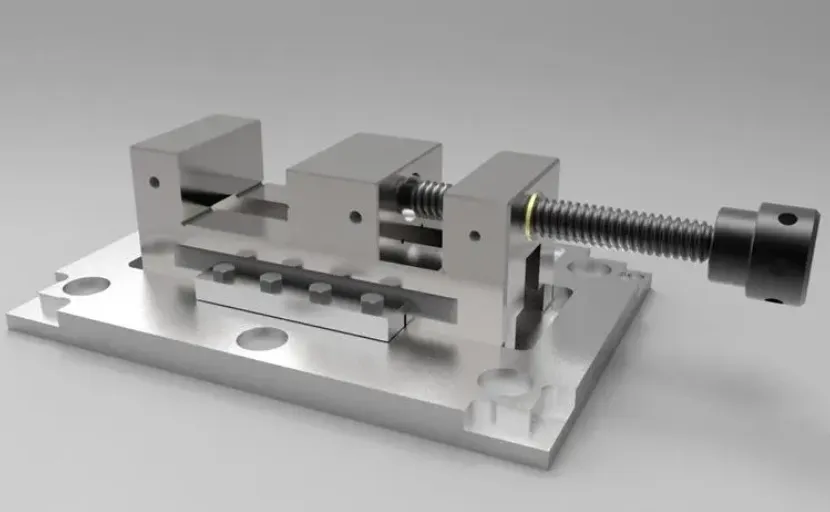

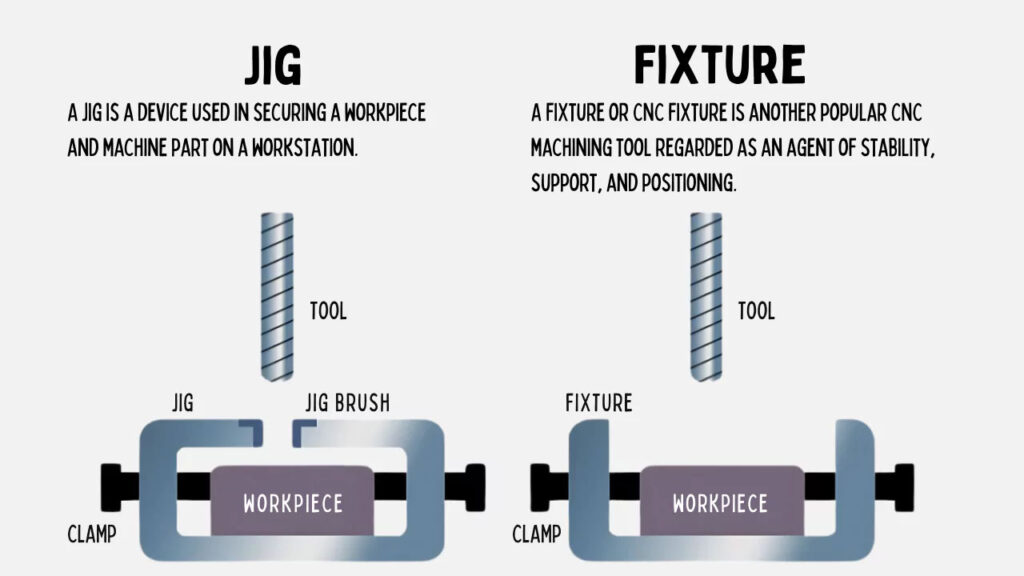

A fixture is a mechanical device that secures a workpiece to machining equipment to maintain its precise position. Fixtures are commonly used on various milling, turning, drilling, and threading machines to ensure precision and stability.

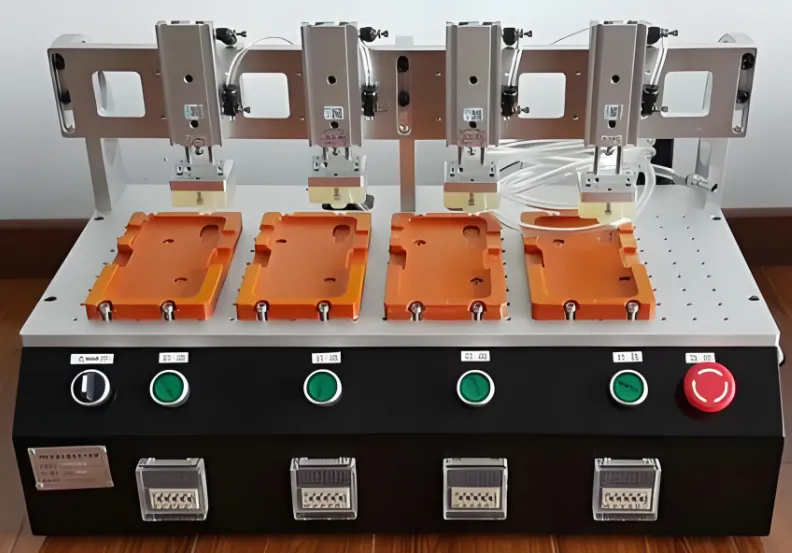

A fixture holds a workpiece in place during machining, capturing it through a series of positioning and clamping operations. Unlike fixtures, jigs are specifically designed to process a specific workpiece or product. Jigs are commonly used in automated machining lines and are widely used in industrial production applications such as welding, injection molding, stamping, and die-casting.

Both fixtures and jigs are used to maintain the exact position of the workpiece during machining and improve machining accuracy. However, they also have some essential differences.

Both fixtures and jigs are commonly used tools in manufacturing. The key differences between the two lie in their purpose, design, and flexibility. Jigs focus on controlling the position or movement of a specific workpiece and are primarily used in automated production lines to improve efficiency and accuracy. Fixtures, on the other hand, focus on securing the workpiece for processing or inspection.