Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

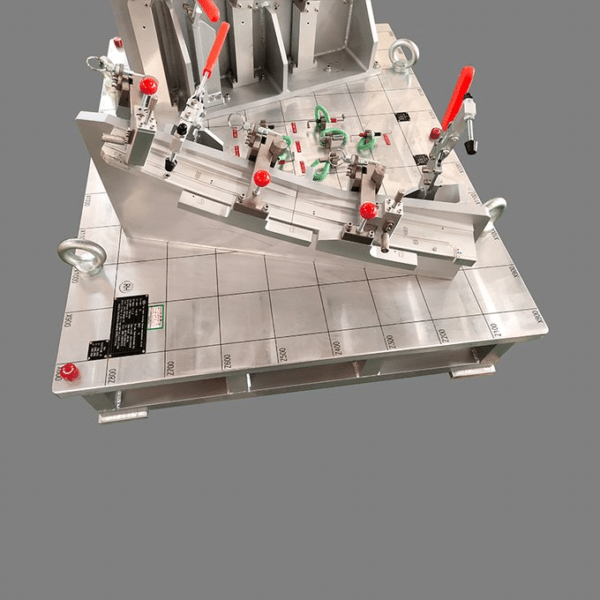

This Custom 3D CMM welding holding fixtures are designed to streamline the inspection process, improve quality control and efficiency while assuring accurate measurements of welded components.

| Brand Name | OEM |

| Product Name | Metal Stamping Die/Mould |

| Tolerance | ±0.002mm |

| Material | SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | ISO9001 |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer’s requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | Depends on customer’s production capacity |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer’s requirements |