Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

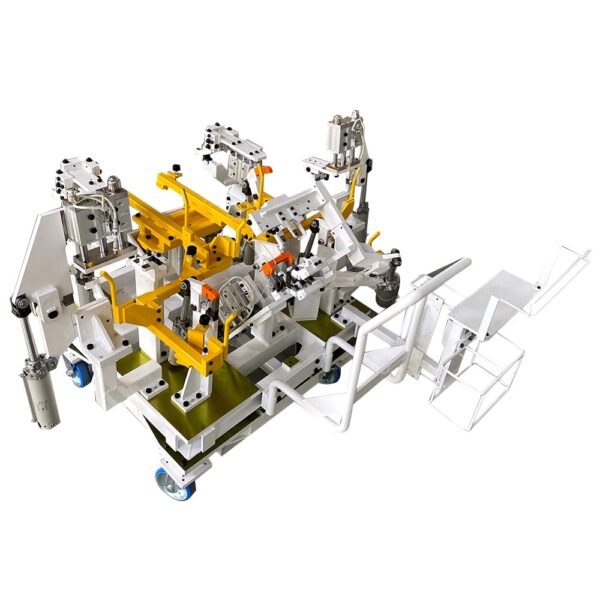

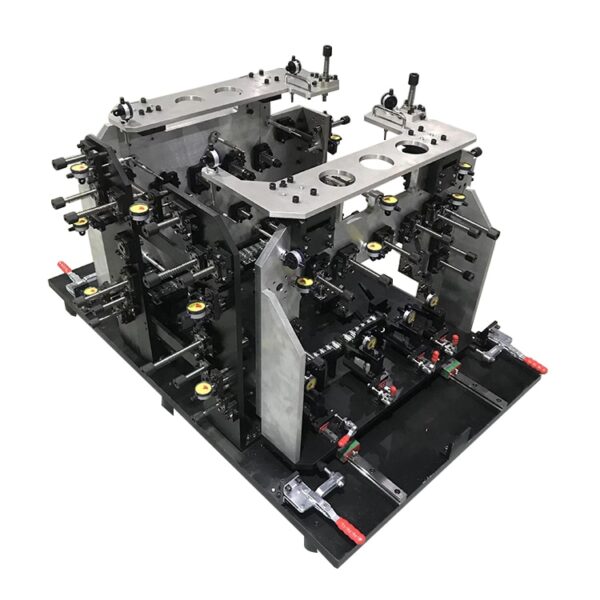

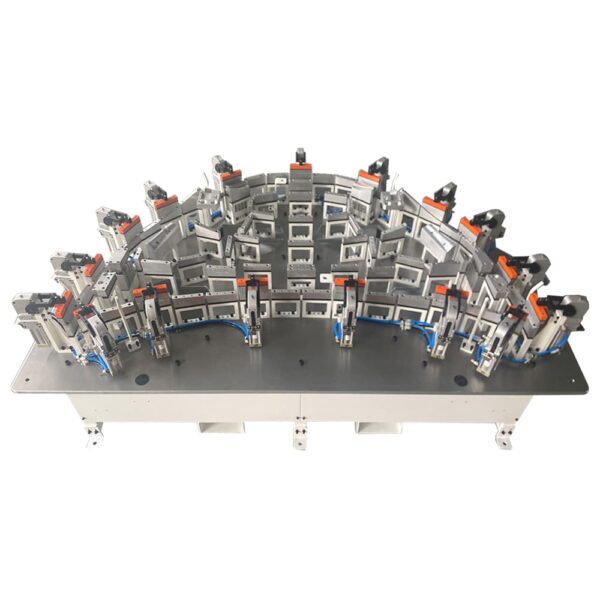

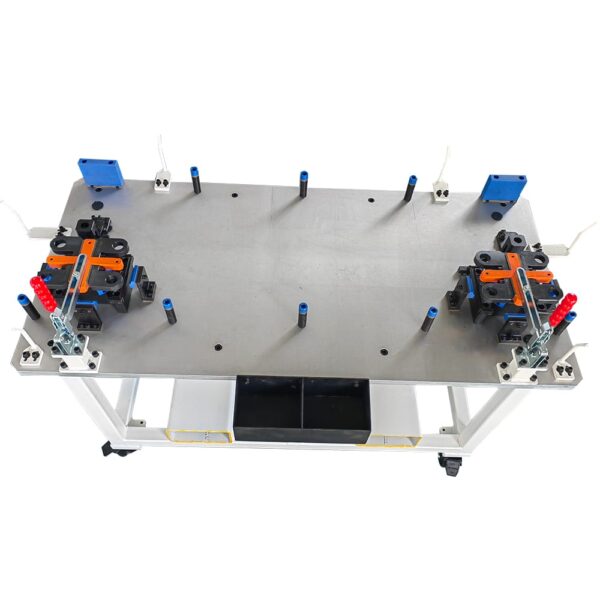

Custom Auto Precision Welding Tool Checking Fixtures are specialized tools used in automotive manufacturing processes to ensure the accuracy and precision of welding operations.

|

Name

|

Custom Auto Precision Welding Tool Checking Fixture

|

|

Materials

|

Aluminum / Steel / Alloy steel / Stainless steel / Brass,ect.

|

|

Surface Treatment

|

Anodizing, polishing , sand casting , zinc/nickel/chrome plating / painting / heat treatment ect.

|

|

Tolerance

|

+/-0.01mm~+/-0.05mm, according to customer’s requirements

|

|

Processing Equipment

|

CNC machining center, CNC lathe, Grinding machine,drilling machine, EDM, wire-cutting machine ect.

|

|

Logo Method

|

Laser engraving / CNC engraving / Screen printing ect.

|

|

Color

|

Silver / black / Gold / orange / gray, as client’s requirements

|

|

Service Project

|

To provide production design, production and technical service, mould development and processing, etc

|