Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

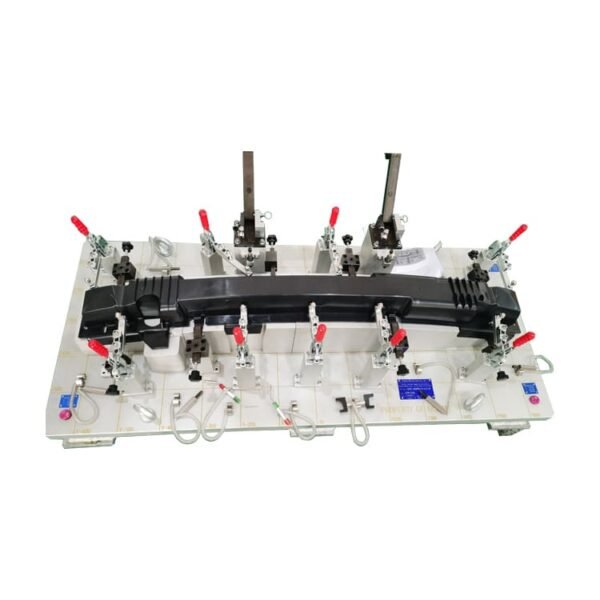

A professional OEM auto side frame assembly checking fixture is a specialized tool used in automotive manufacturing to ensure the accuracy and quality of the side frame assembly process.

|

Type

|

ISO9001 factory provides custom precision various checking fixture, test fix

|

|

Materials

|

1. Metal:Aluminum/Steel/Alloy steel/Stainless steel/Brass, etc.

|

|

Color

|

Silver, Gray, Black ,Gold or as client’s requirement

|

|

Surface Roughness

|

Ra0.4 ( without polishing or grinding)

|

|

Logo Method

|

Laser Engraving, CNC Engraving, Screen-printing etc.

|

|

Surface Finish

|

Anodize, Polishing, Zinc/Nickel/Chrome/Gold Plating, Sand Blasting, ect.

|

|

Tolerance

|

+/- 0.01–0.05mm / can also be customized

|

|

Certificate

|

ISO9001:2008

|

|

Processing equipments

|

CNC machining center,CNC lathe, Grinding machine, Automatic lathe machine, Conventional lathe machine,Milling machine,Drilling

machine,EDM,Wire-cutting machine,CNC bending machine etc |

|

Testing machine

|

Coordinate measuring machine,micrometer,Caliper etc

|