Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

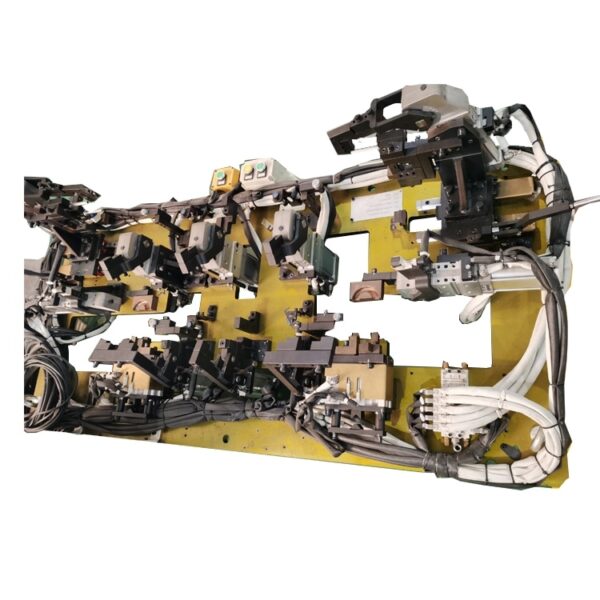

This Auto welding fixtures play an essential part in ensuring constant and effective welding processes in a manufacturing line production setting. It improves efficiency, decrease errors, and improve your overall performance of weldable components.

| Customized support | OEM, ODM, Software reengineering |

| Place of Origin | Guangdong, China |

| Brand Name | Favimiall |

| Model Number | FV-W-005 |

| Product name | Auto Welding Fixture For Production Line Manufacturing |

| Function | Components Checking |

| Delivery time | 30 Days |

| MOQ | 1PC |

| Material | Steel |

| Packaging: | Wooden Crate |