Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

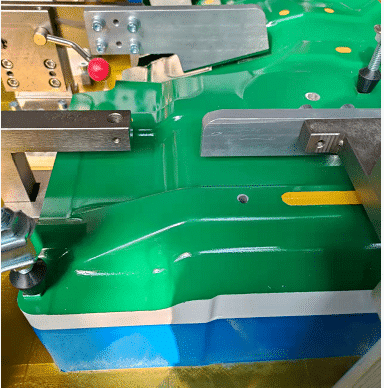

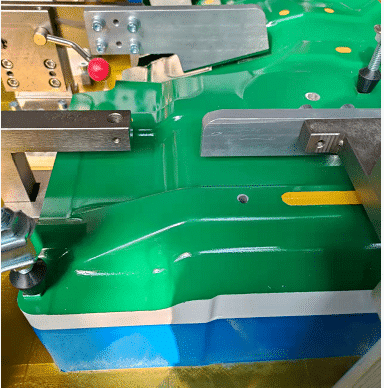

our customized automotive inspection jigs offer precise measurement capabilities, customized designs, multifunctionality, ergonomic features, durability, integration with testing equipment, traceability

| item | value |

| Place of Origin | Shenzhen China |

| Micro Machining or Not:

|

Micro Machining

|

| Brand Name | other |

| Model Number | other |

| bottom plate | Aluminum 6061 |

| Is it a standard part | Non-standard parts |

| surface treatment | spray paint |

| MOQ | 1 Set |

| Material Capabilities:

|

Aluminum, Hardened Metals, Stainless Steel, Steel Alloys…

|

| Require:

|

3D digital model 2D drawings |